Anodizing aluminium high-precision parts and high-end cosmetic parts to exact dimensions

Oxidation of aluminium is a natural process. Anodizing accelerates this natural oxidation process, and converts the top layer of the aluminium into aluminium oxide without affecting the material’s metal appearance. Regular anodized products have a smooth, matt finish that offers durable protection against corrosion and are harder and more wear-resistant than parts that have not been anodized.

You can turn to Adruu for both high-precision parts with high accuracies and tolerances and for high-quality cosmetic parts. With Adruu you can be certain that your parts will be anodized to the exact dimensions you require: micron-accurate! We have a specially developed pickling process for high-quality cosmetic parts to remove any irregularities and create a nicely even surface.

Cold and hot sealing for superior layers

Adruu can apply special cold and hot sealing to create superior layers on the aluminium that are highly corrosion resistant. Corrosion testing shows that Adruu is at the forefront as regards the quality of the anodized layers.

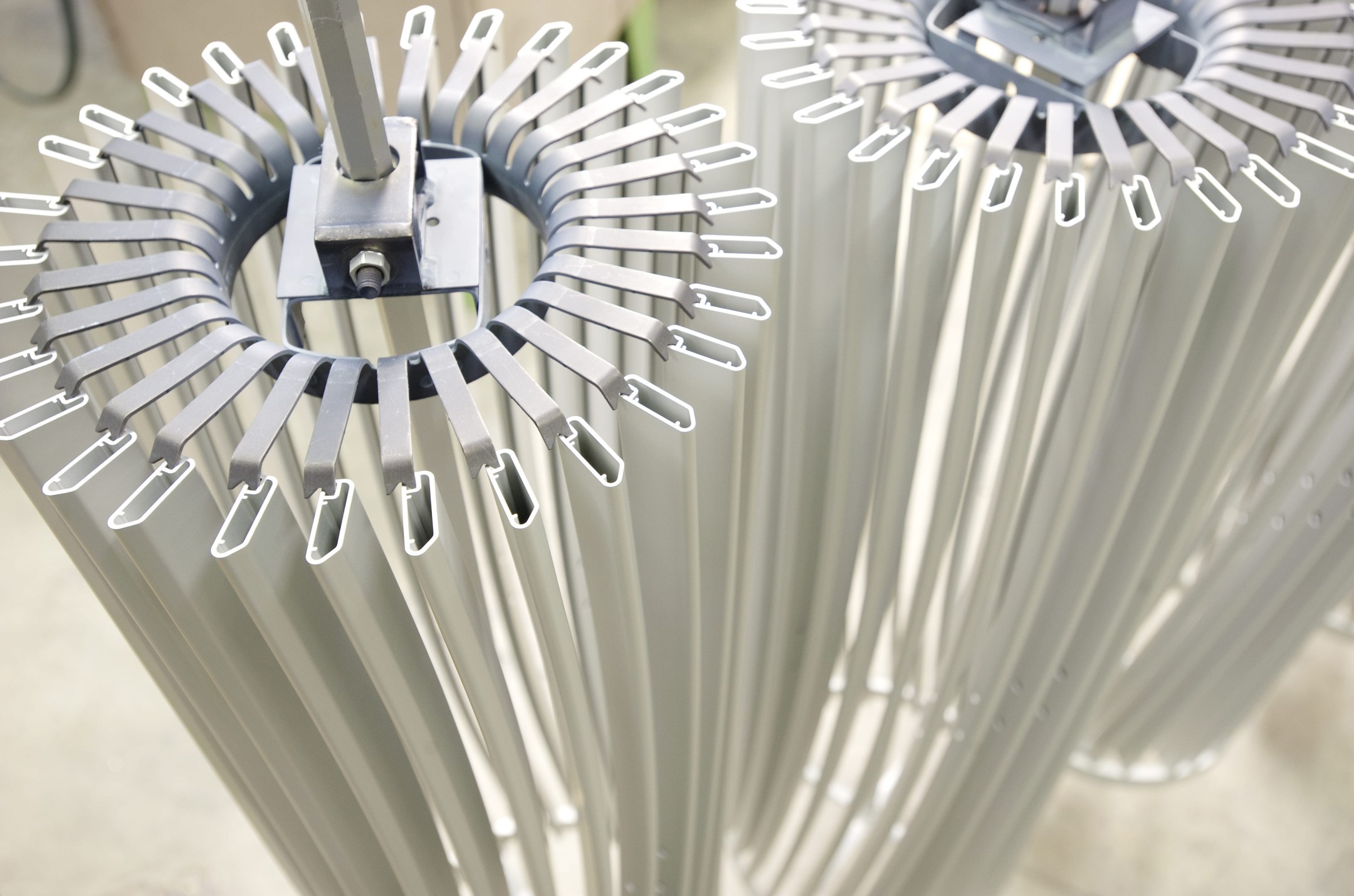

Large and small lines for anodizing to exact dimensions

Since Adruu can anodize parts on two lines, a large (4000 x 1200 x 500 mm) and a small line. We can treat aluminium parts very quickly and effectively, from single products to millions of parts a year.

Quality guarantee for anodizing to exact dimensions

Adruu checks all baths in its own laboratory on a daily basis. All results are stored to ensure that consistent quality is assured on a continual basis. Adruu has various measuring equipment like a 3-D measuring machine, roughness testers, layer thickness testers, a Taber-Abraser and various gauges to perform receiving and final inspections. Adruu treats products according to the most common standards such as Mil Specs and automotive standards like TL-212.